Plastic welding with steel wool

-

The Spin Doctor

- Posts: 4096

- Joined: Mon Mar 16, 2020 6:17 pm

- Has thanked: 2636 times

- Been thanked: 1525 times

Plastic welding with steel wool

I was popping up one of my regular YouTube vids in my channel (which is www.youtube.com/survivalskillsuk if you're interested) and having done that I looked to see what other interesting videos might have appeared.

And I found this one about melting steel wool into plastic to reinforce the repair and using cable ties as a source of fresh plastic.

No idea what kind of plastic it would work on, but for a rough and ready fix, it seems quick and surprisingly neat.

And I found this one about melting steel wool into plastic to reinforce the repair and using cable ties as a source of fresh plastic.

No idea what kind of plastic it would work on, but for a rough and ready fix, it seems quick and surprisingly neat.

"If a man does not keep pace with his companions, perhaps it is because he hears a different drummer." Henry David Thoreau

www.ko-fi.com/survivalskills www.survivalskillsridertraining.co.uk www.facebook.com/survivalskills

www.ko-fi.com/survivalskills www.survivalskillsridertraining.co.uk www.facebook.com/survivalskills

- Yorick

- Posts: 16801

- Joined: Sat Mar 14, 2020 8:20 pm

- Location: Paradise

- Has thanked: 10336 times

- Been thanked: 6915 times

Re: Plastic welding with steel wool

I like the cable tie ideaThe Spin Doctor wrote: ↑Tue Jul 25, 2023 8:29 pm I was popping up one of my regular YouTube vids in my channel (which is www.youtube.com/survivalskillsuk if you're interested) and having done that I looked to see what other interesting videos might have appeared.

And I found this one about melting steel wool into plastic to reinforce the repair and using cable ties as a source of fresh plastic.

No idea what kind of plastic it would work on, but for a rough and ready fix, it seems quick and surprisingly neat.

- mangocrazy

- Posts: 6984

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2415 times

- Been thanked: 3659 times

Re: Plastic welding with steel wool

I was aware of the cable tie trick (coloured cable ties to match the plastic you're welding), but the steel wool reinforcement is a great idea.

There is no cloud, just somebody else's computer.

- Yorick

- Posts: 16801

- Joined: Sat Mar 14, 2020 8:20 pm

- Location: Paradise

- Has thanked: 10336 times

- Been thanked: 6915 times

Re: Plastic welding with steel wool

I've often used tiny pins, heated with a blow torch.mangocrazy wrote: ↑Tue Jul 25, 2023 9:49 pm I was aware of the cable tie trick (coloured cable ties to match the plastic you're welding), but the steel wool reinforcement is a great idea.

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

Quick! Publish it!

https://journals.sagepub.com/doi/full/1 ... 0901800202

Metal Fibre Reinforced Composite – Potentialities and Tasks

I joke, but that's pretty much what's going on here! It's a metal reinforced polymer, which conceptually is exactly the same as carbon fibre (hence the proper name "Carbon Fibre Reinforced Polymer") - just with metals rather than carbon.

https://journals.sagepub.com/doi/full/1 ... 0901800202

Metal Fibre Reinforced Composite – Potentialities and Tasks

I joke, but that's pretty much what's going on here! It's a metal reinforced polymer, which conceptually is exactly the same as carbon fibre (hence the proper name "Carbon Fibre Reinforced Polymer") - just with metals rather than carbon.

- Horse

- Posts: 11621

- Joined: Sun Mar 15, 2020 11:30 am

- Location: Always sunny southern England

- Has thanked: 6238 times

- Been thanked: 5120 times

Re: Plastic welding with steel wool

Hmmm do you think it would be possible to reinforce concrete stronger by using steel reinforcement bar (long name though)?Mr. Dazzle wrote: ↑Wed Jul 26, 2023 8:42 am Quick! Publish it!

https://journals.sagepub.com/doi/full/1 ... 0901800202

Metal Fibre Reinforced Composite – Potentialities and Tasks

I joke, but that's pretty much what's going on here! It's a metal reinforced polymer, which conceptually is exactly the same as carbon fibre (hence the proper name "Carbon Fibre Reinforced Polymer") - just with metals rather than carbon.

Even bland can be a type of character

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

There're a few bridges here in MK where the steel re-bar is made out of carbon fibre  (They have warning signs attached, presumably for maintenance reasons) I assume it's for corrosion purposes but the idea of lightweight concrete reinforcement always tickles me.

(They have warning signs attached, presumably for maintenance reasons) I assume it's for corrosion purposes but the idea of lightweight concrete reinforcement always tickles me.

Reinforced concrete is a fun one, it's actually a "double composite". The concrete is a composite, then the steel reinforcement makes it a composite again.

Reinforced concrete is a fun one, it's actually a "double composite". The concrete is a composite, then the steel reinforcement makes it a composite again.

- Rockburner

- Posts: 4404

- Joined: Sun Mar 15, 2020 11:06 am

- Location: Hiding in your blind spot

- Has thanked: 7852 times

- Been thanked: 2555 times

Re: Plastic welding with steel wool

Steel itself is an alloy, so conceptually, it's a triple composite....Mr. Dazzle wrote: ↑Wed Jul 26, 2023 9:04 am There're a few bridges here in MK where the steel re-bar is made out of carbon fibre(They have warning signs attached, presumably for maintenance reasons) I assume it's for corrosion purposes but the idea of lightweight concrete reinforcement always tickles me.

Reinforced concrete is a fun one, it's actually a "double composite". The concrete is a composite, then the steel reinforcement makes it a composite again.

non quod, sed quomodo

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

The key thing about composites though is they're macroscopic, whereas alloys are microscopic.

Compounds - Atomic scale

Alloys - Microscopic

Composites - Macroscopic

It's slide 2 in my "composites for non composites people" presentation

Compounds - Atomic scale

Alloys - Microscopic

Composites - Macroscopic

It's slide 2 in my "composites for non composites people" presentation

- mangocrazy

- Posts: 6984

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2415 times

- Been thanked: 3659 times

Re: Plastic welding with steel wool

I was under the impression that the benefit that steel rebar brings to reinforced concrete is that steel is ductile whereas concrete is not, so you get the benefits of both sets of properties. Isn't CF essentially brittle, and as such is not offering the same benefit?Mr. Dazzle wrote: ↑Wed Jul 26, 2023 9:04 am There're a few bridges here in MK where the steel re-bar is made out of carbon fibre(They have warning signs attached, presumably for maintenance reasons) I assume it's for corrosion purposes but the idea of lightweight concrete reinforcement always tickles me.

Having said that, the use of mild steel rebar in concrete is a double-edged sword. As long as water can't get to the rebar and corrosion is inhibited, all is good. Once rebar goes bad and corrodes it will expand and blow the concrete apart. For that reason I've never understood why stainless rebar is not more widely used - cost, I guess.

I've formed a couple of slabs in building a BBQ/smoker in the garden and I used good old stainless steel threaded rod as rebar.

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

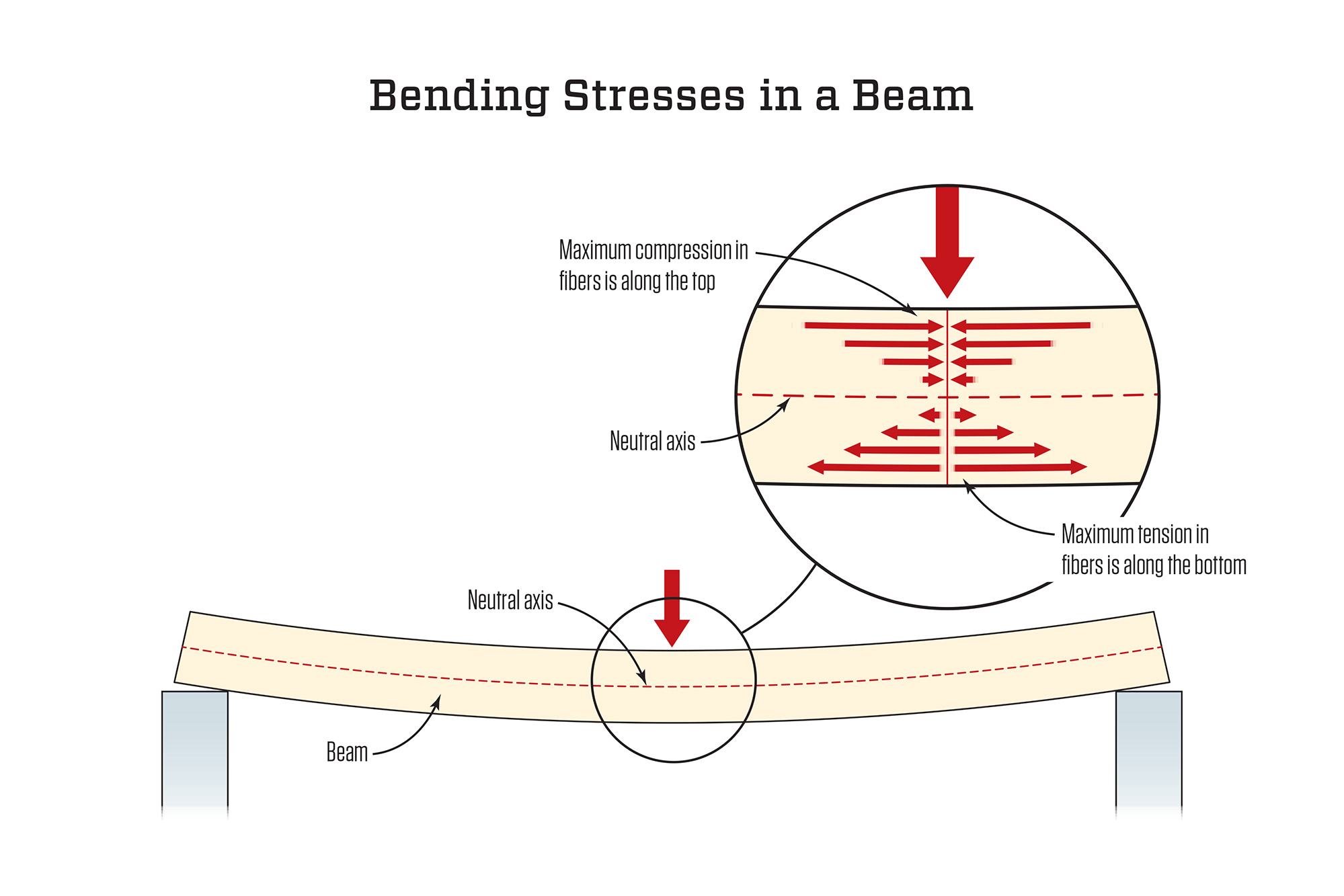

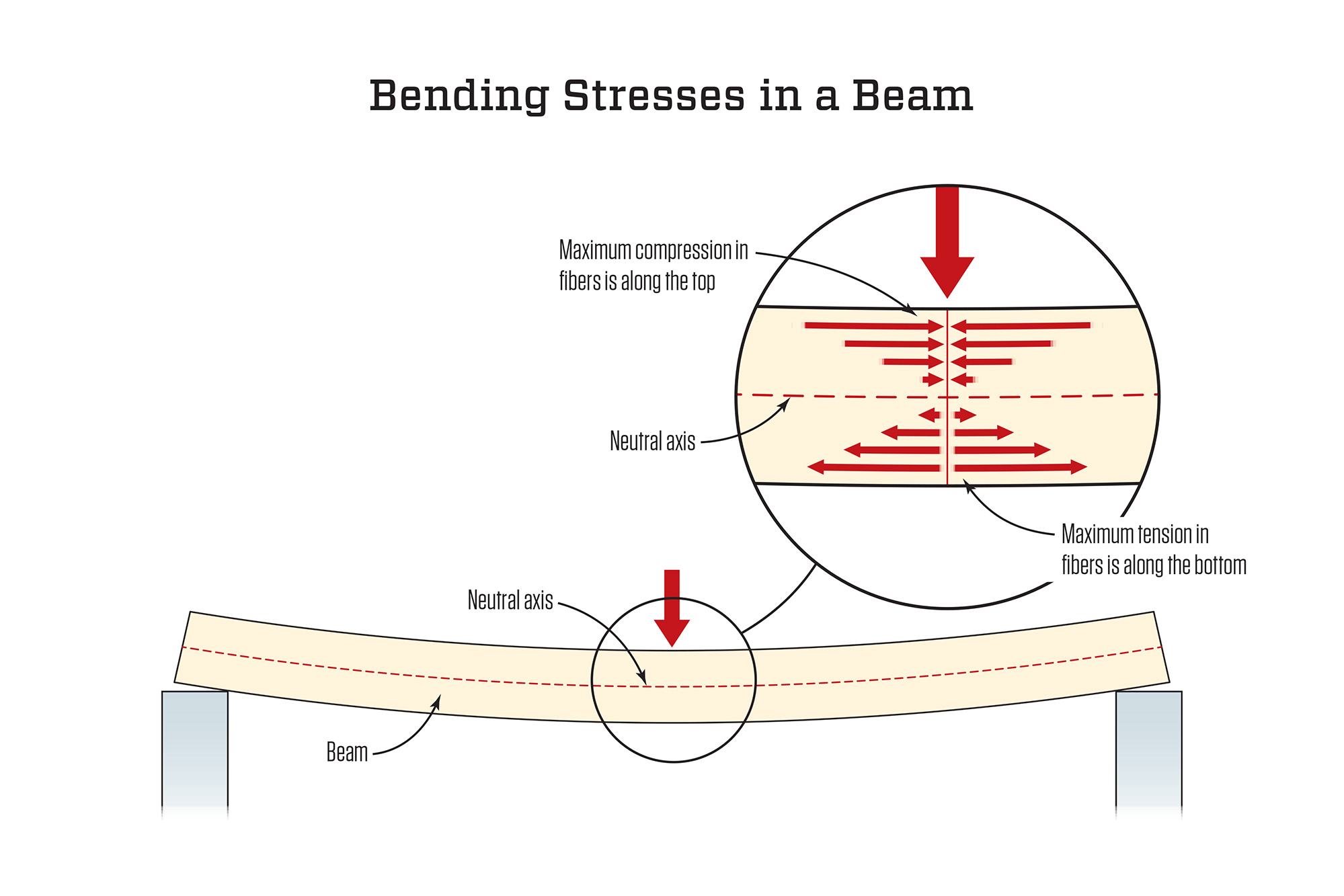

It's cause concrete is absolutely piss poor in tension, basically rich tea biscuit. Steel on the other hand is excellent in tension and very cheap. Concrete is amazing in compression.

Whenever you have something in bending, like a bridge, the top is in compression and the bottom is in tension. Hence, concrete up top, steel down below. You generally have the steel encased in the concrete though to protect it, to tranfer load between the two and to have the right shape.

If you look at bridges they're often cracked up to the mid point, which is fine. In the tension section the steel is doing all the work so you don't care if the concrete cracks (from a pure strength POV).

Carbon fibre on teh other hand is bloody spectacular in terms of tensile strength. Many multiples stronger than steel in some cases. Just costs a smidge and you can't bend it into shape etc.

Whenever you have something in bending, like a bridge, the top is in compression and the bottom is in tension. Hence, concrete up top, steel down below. You generally have the steel encased in the concrete though to protect it, to tranfer load between the two and to have the right shape.

If you look at bridges they're often cracked up to the mid point, which is fine. In the tension section the steel is doing all the work so you don't care if the concrete cracks (from a pure strength POV).

Carbon fibre on teh other hand is bloody spectacular in terms of tensile strength. Many multiples stronger than steel in some cases. Just costs a smidge and you can't bend it into shape etc.

- mangocrazy

- Posts: 6984

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2415 times

- Been thanked: 3659 times

Re: Plastic welding with steel wool

You had that slide ready to go, didn't you?

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

It's like page 2 of the structures design course and the first question I ask in interviews  You'd be amazed how many people (who are going for Engineering jobs) don't even know this. Start with the basics

You'd be amazed how many people (who are going for Engineering jobs) don't even know this. Start with the basics

https://www.google.com/search?client=op ... 17&dpr=0.9

https://www.google.com/search?client=op ... 17&dpr=0.9

- Count Steer

- Posts: 11884

- Joined: Mon Jul 19, 2021 4:59 pm

- Has thanked: 6413 times

- Been thanked: 4797 times

Re: Plastic welding with steel wool

If you reach the point where ductility comes into play I think you've overloaded things a bit. ie permanently deformed things.mangocrazy wrote: ↑Wed Jul 26, 2023 12:16 pmI was under the impression that the benefit that steel rebar brings to reinforced concrete is that steel is ductile whereas concrete is not, so you get the benefits of both sets of properties.Mr. Dazzle wrote: ↑Wed Jul 26, 2023 9:04 am There're a few bridges here in MK where the steel re-bar is made out of carbon fibre(They have warning signs attached, presumably for maintenance reasons) I assume it's for corrosion purposes but the idea of lightweight concrete reinforcement always tickles me.

So, now I've convinced myself that ductility matters 'cos the structure will weaken rather than fail catastrophically if overloaded to a degree

Doubt is not a pleasant condition.

But certainty is an absurd one.

Voltaire

But certainty is an absurd one.

Voltaire

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

I'm not a civil engineer, so I dunno which normally goes first - concrete 'crushing' on the top or the steel 'stretching' on the bottom. I suppose you'd normally design it so both happen at the same time, otherwise you've got redundant amounts of one of them.

Where's dodgy these days

Where's dodgy these days

- Count Steer

- Posts: 11884

- Joined: Mon Jul 19, 2021 4:59 pm

- Has thanked: 6413 times

- Been thanked: 4797 times

Re: Plastic welding with steel wool

I imagine that they're generally overengineered for the traffic at the time of construction and (hopefully!) for the traffic anticipated in the future. Unfortunately a lot of them didn't anticipate the volume of traffic or the weight of some of it when they were built. Mind you, some of the v old stone bridges have lasted as if the planned design life was a v v long time.Mr. Dazzle wrote: ↑Wed Jul 26, 2023 12:53 pm I'm not a civil engineer, so I dunno which normally goes first - concrete 'crushing' on the top or the steel 'stretching' on the bottom. I suppose you'd normally design it so both happen at the same time, otherwise you've got redundant amounts of one of them.

Where's dodgy these days

(I'm not a civil engineer either but I did go to check out the Applied Physics course at Bath Uni and they showed me a rather impressive scale model bridge made of perspex. You could load it in different ways and watch the stresses and strains building using polarised light. Quite nifty).

Doubt is not a pleasant condition.

But certainty is an absurd one.

Voltaire

But certainty is an absurd one.

Voltaire

-

Mr. Dazzle

- Posts: 14068

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2572 times

- Been thanked: 6300 times

Re: Plastic welding with steel wool

Good old polarsied light stress analysis. It doesn't really work when you've got loads of different materials under consideration sadly, 'cause your model is all made out of one kinda plastic.

Plus rather more prosaically, we've got 'puters now.

Plus rather more prosaically, we've got 'puters now.

- Skub

- Posts: 12237

- Joined: Mon Mar 16, 2020 5:32 pm

- Location: Norn Iron

- Has thanked: 9901 times

- Been thanked: 10212 times

Re: Plastic welding with steel wool

Very useful. There have been times when I could have used that wire wool tip.The Spin Doctor wrote: ↑Tue Jul 25, 2023 8:29 pm I was popping up one of my regular YouTube vids in my channel (which is www.youtube.com/survivalskillsuk if you're interested) and having done that I looked to see what other interesting videos might have appeared.

And I found this one about melting steel wool into plastic to reinforce the repair and using cable ties as a source of fresh plastic.

No idea what kind of plastic it would work on, but for a rough and ready fix, it seems quick and surprisingly neat.

"Be kind to past versions of yourself that didn't know what you know now."

Walt Whitman

https://soundcloud.com/skub1955

Walt Whitman

https://soundcloud.com/skub1955

- Horse

- Posts: 11621

- Joined: Sun Mar 15, 2020 11:30 am

- Location: Always sunny southern England

- Has thanked: 6238 times

- Been thanked: 5120 times

Re: Plastic welding with steel wool

IIRC some concrete beams used in buildings are cast slightly curved, so that they flatten under their own weight and loading when in place.Count Steer wrote: ↑Wed Jul 26, 2023 12:44 pm

So, now I've convinced myself that ductility matters 'cos the structure will weaken rather than fail catastrophically if overloaded to a degreeI guess you'd have to keep testing eg the sag in a bridge under load to know that it had been overloaded - but the cracked concrete would probably tell you that too.

Even bland can be a type of character

- Horse

- Posts: 11621

- Joined: Sun Mar 15, 2020 11:30 am

- Location: Always sunny southern England

- Has thanked: 6238 times

- Been thanked: 5120 times

Re: Plastic welding with steel wool

The company my dad worked for had that perspex polarised light idea in the company magazine, probably early 1970s. The example was a crane hook under load.Count Steer wrote: ↑Wed Jul 26, 2023 1:02 pm

(I'm not a civil engineer either but I did go to check out the Applied Physics course at Bath Uni and they showed me a rather impressive scale model bridge made of perspex. You could load it in different ways and watch the stresses and strains building using polarised light. Quite nifty).

Even bland can be a type of character