I've owned/ridden/raced pretty much every iteration of 748/916/955/996/998 over the years so Ducati ownership doesn't strike fear in my heart, plus I'd done my research and was aware of all the myriad of issues that afflicted Multistrada's of that vintage.

So money changed hands and I rode away on my shiny white 'strada....

....and a few days later rode it back to the dealership so that they could sort out the reluctance to start, the leaking fuel tank, the misbehaving electrics and more. To their credit the dealership didn't argue and handed over a brand, with less than 300 miles on the clock, new Yamaha MT09 Tracer thing, with instructions to treat as if it were my own while they sorted out the 'strada.

So I did, I had it for about 8 weeks and put over 4,000 miles on it....

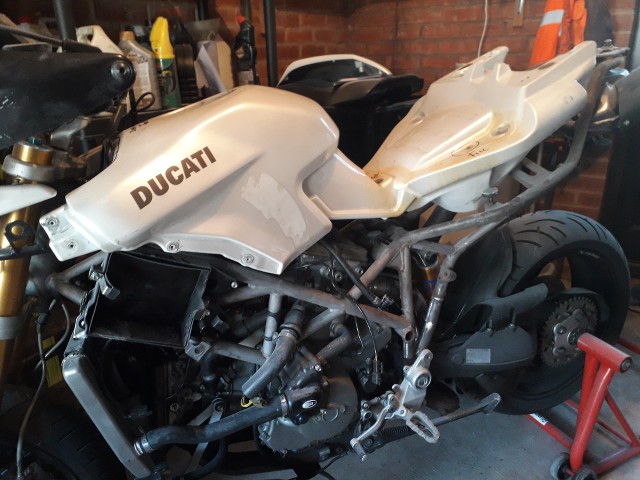

...and after 8 weeks, with the dealership making little progress with my Ducati and the novelty of the Tracer wearing off (and also fearing that they'd find out exactly what I'd done to their previously pristine Yamaha while I had it), I made the suggestion that a deal could be done to make all parties happy. Long and short of it, they gave me about half the purchase price back and I took the Ducati back to sort out for myself.

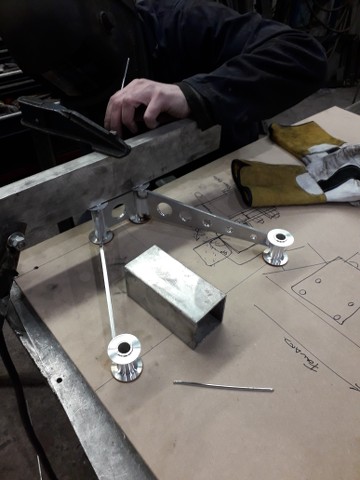

With the invaluable help of Nelly at Cornerspeed Ducati and the repository of all 'strada knowledge that is the Multistrada owners forum all of the problems were fixed and then work started on getting the best out of it. Uprated brakes, sorted suspension, tweaked geometry, lightened flywheel and so on....

The bike was awesome. I used it for commuting all year round in filthy weather...

Pottering around the Peak District - where I'd moved to - checking out the roads and the scenery...

And the amusing, and apt, place names...

Popping half way down the country to pick up a pair of scrubs and then finding you'd forgotten to pack the ratchet straps...

And hooning around on it, riding it like a giant supermoto replete with MX lid and stormtrooper boots....

On awesome twisty, winding, Alpine style roads like these...

...and embarassing the latest greatest superbikes.

But.......