Ducati Multistretta 1098S

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

Dropped the engine off with Nelly at Cornerspeed for him to do the voodoo that he does so well. Also chucked in the swingarm, for new bearings, and the rear shock, for stiffer spring and a new remote preload adjuster hose. He reports that supply of parts and consumables is becoming an issue; Ducati UK have been supplying to all orders placed with them, irrespective of where in the world the customer is based, and Ducati HQ have not been sending out any meaningful quantities of new stock - presumably because their supply chain has been decimated by results of lockdown etc. in Italy. Nelly is a Motul devotee and can only now buy oil in 44 gallon drums and anti-freeze is rarer than rocking horse pooh. Hoping for 3 weeks or so for the work to be done.

I also went over to the other side of Mansfield to visit a paint shop, recommended by a Harley riding delivery driver who regularly delivers to work and who has taken an interest in the Multistretta since it has been in the factory, called Vale Paints. Liked what I saw there and they're going to powder coat the frame, bead burnish and lacquer the tank (I'll scotch brite it to give it a brushed look between the burnishing and the lacquering) and paint the bodywork.

I told the guy who runs the place that I was looking for the paint finish to replicate the factory quality; he said he can't normally paint that badly but he'll give it a go........

Going for flat black bodywork with white and red logo's.

They had a fibreglass bodied car in the paint bay having all of its trim refitted after painting. The back end was peeping out and I thought it was an E-type but it turned out to be a "Rotherham". Made in the 1950's it had a full fibreglass body with no chassis, the suspension and engine and everything else bolted straight to the body. Designed by an aircraft engineer and the one they had is the only one that's still with the original owner. Never heard of them, has anyone else?

Going to pause work on the tank to finish the frame next week, welding in the cross-members and mounting brackets that had been tacked in and adding a couple of gussets to strengthen the frame between the engine mounts (a known weak point when you start chucking serious power out), and then drop it off for powder coating.

I also went over to the other side of Mansfield to visit a paint shop, recommended by a Harley riding delivery driver who regularly delivers to work and who has taken an interest in the Multistretta since it has been in the factory, called Vale Paints. Liked what I saw there and they're going to powder coat the frame, bead burnish and lacquer the tank (I'll scotch brite it to give it a brushed look between the burnishing and the lacquering) and paint the bodywork.

I told the guy who runs the place that I was looking for the paint finish to replicate the factory quality; he said he can't normally paint that badly but he'll give it a go........

Going for flat black bodywork with white and red logo's.

They had a fibreglass bodied car in the paint bay having all of its trim refitted after painting. The back end was peeping out and I thought it was an E-type but it turned out to be a "Rotherham". Made in the 1950's it had a full fibreglass body with no chassis, the suspension and engine and everything else bolted straight to the body. Designed by an aircraft engineer and the one they had is the only one that's still with the original owner. Never heard of them, has anyone else?

Going to pause work on the tank to finish the frame next week, welding in the cross-members and mounting brackets that had been tacked in and adding a couple of gussets to strengthen the frame between the engine mounts (a known weak point when you start chucking serious power out), and then drop it off for powder coating.

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

Finally managed to get the CAD model of the airbox over to the 3D printers. They came back with a price and it was a lot more than I was expecting, in fact on a par with the carbon fibre option. I had been expecting the printed option to be significantly cheaper, based on a comparison between CNC machining and manual machining costs, but the printers explained that the printer they'd be using - because of the size of the airbox - has to use material that can only be bought from the printer manufacturer and it is expensive when compared to other, more readily available, material.

So, I'm going back to the carbon fibre option for the airbox. Because it's proven for use in the application and, well, because carbon fibre...

Spent a few hours at work this morning getting the frame ready for final welding this week. Oooh, me gussets....

...reinforcing the frame in a known weak spot when you start pumping some serious power out.

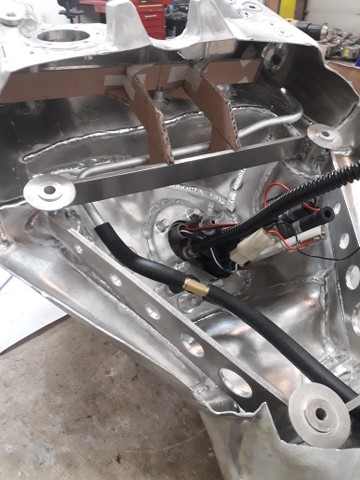

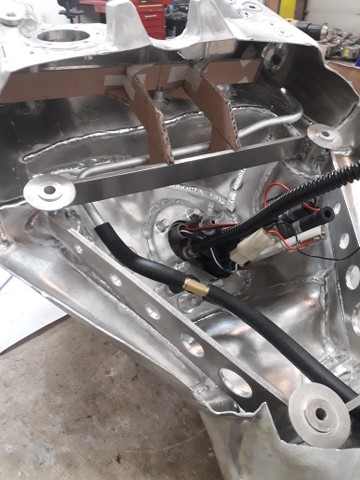

On to the tank. Checked the fit of everything under the pillion seat, it's a busy old place to be with seat hinges, breather valve, vapour recovery tank and all the pipework....

We've started working on the breather tubes and pipes under the seat...

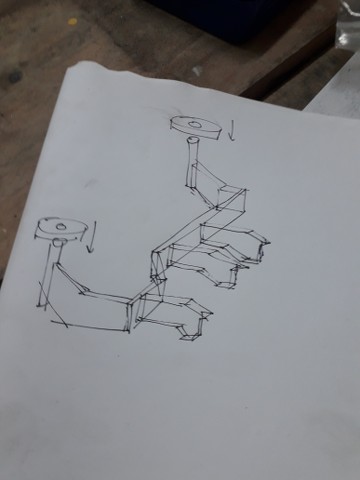

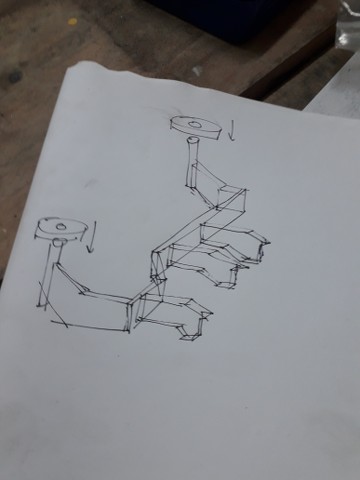

...and the pillion support frame, with the aid of the other kind of CAD - Cardboard Aided Design.

The back of the tank sits on a cross-member on the frame and there's an M8 threaded boss welded into the tank underside which is used to bolt the tank down....

And the pillion seat squab sits, on rubber bumpers, on top of the tank where the black circles are...

So knocked up a couple of 6mm thick aluminium discs with 8.5mm holes through the middle, which will be welded to the tank top where the bumpers sit...

The plan is to fabricate a frame from 6mm plate aluminium that is welded to the back of the rider's seat support frame and also sits on top of the M8 boss at the back of the tank....

The dog leg in it is to clear the breather valve. There's holes in the tank top and the plan is to weld 8mm dia round bar to the ends of the support frame legs and these will run up through the tank skin and the discs....

...and the round bar will be welded to the discs, but not the tank skin. So the forces from the pillion seat go into the support frame and then into the bike frame, and not through the tank skin.

So, I'm going back to the carbon fibre option for the airbox. Because it's proven for use in the application and, well, because carbon fibre...

Spent a few hours at work this morning getting the frame ready for final welding this week. Oooh, me gussets....

...reinforcing the frame in a known weak spot when you start pumping some serious power out.

On to the tank. Checked the fit of everything under the pillion seat, it's a busy old place to be with seat hinges, breather valve, vapour recovery tank and all the pipework....

We've started working on the breather tubes and pipes under the seat...

...and the pillion support frame, with the aid of the other kind of CAD - Cardboard Aided Design.

The back of the tank sits on a cross-member on the frame and there's an M8 threaded boss welded into the tank underside which is used to bolt the tank down....

And the pillion seat squab sits, on rubber bumpers, on top of the tank where the black circles are...

So knocked up a couple of 6mm thick aluminium discs with 8.5mm holes through the middle, which will be welded to the tank top where the bumpers sit...

The plan is to fabricate a frame from 6mm plate aluminium that is welded to the back of the rider's seat support frame and also sits on top of the M8 boss at the back of the tank....

The dog leg in it is to clear the breather valve. There's holes in the tank top and the plan is to weld 8mm dia round bar to the ends of the support frame legs and these will run up through the tank skin and the discs....

...and the round bar will be welded to the discs, but not the tank skin. So the forces from the pillion seat go into the support frame and then into the bike frame, and not through the tank skin.

Last edited by millemille on Sat Jul 11, 2020 4:16 pm, edited 1 time in total.

- weeksy

- Site Admin

- Posts: 23416

- Joined: Sat Mar 14, 2020 12:08 pm

- Has thanked: 5450 times

- Been thanked: 13085 times

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

Insomnia and Ebay are a terrible combination....

....there is now a carbon fibre chin piece, belly pan, tail trim and a set of carbon fibre hand-guards winging their way to me from various parts of the world.

....there is now a carbon fibre chin piece, belly pan, tail trim and a set of carbon fibre hand-guards winging their way to me from various parts of the world.

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

Frame is now finished. All the tacked in pieces are fully welded and the gussets are in as well...

...the frame's going to have a quick shot blast at a place round the corner from work and then all being well it'll go for powder coating Wednesday.

Made good progress with the tank.

The support frame is in, as per the sketch.....

With the round bar uprights running up through the tank skin...

And the round discs welded to the tank skin and then the round bar welded to the disc....

The top face will get linished flat. There's two more plates to be welded between the pillion seat support and the rider seat support frame and then the internal load bearing work is done. We'll cut the tacks that are holding the front top section on to remove it and this will allow the dents to be hammered out from the inside and the two breather pipes from the filler to be bent and welded in.

Then it top back on, flexible hoses clamped down, seat pan on and everything fully welded. Two more weeks I think/hope...

...the frame's going to have a quick shot blast at a place round the corner from work and then all being well it'll go for powder coating Wednesday.

Made good progress with the tank.

The support frame is in, as per the sketch.....

With the round bar uprights running up through the tank skin...

And the round discs welded to the tank skin and then the round bar welded to the disc....

The top face will get linished flat. There's two more plates to be welded between the pillion seat support and the rider seat support frame and then the internal load bearing work is done. We'll cut the tacks that are holding the front top section on to remove it and this will allow the dents to be hammered out from the inside and the two breather pipes from the filler to be bent and welded in.

Then it top back on, flexible hoses clamped down, seat pan on and everything fully welded. Two more weeks I think/hope...

- G.P

- Posts: 1944

- Joined: Sun Mar 15, 2020 9:12 pm

- Location: Wiltshire

- Has thanked: 2029 times

- Been thanked: 1310 times

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

RAL3001 Signal Red.

That is supposed to be the same colour as the OEM frame red.

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

i've just bought a 2nd hand flywheel, which I'll attack with the lathe and/or mill to scalp some metal off.

Every V-twin I've had has always responded well to a lightened flywheel, not so much for the change in engine/power characteristics but more the difference it makes in how much easier the bike becomes to throw around.

Every V-twin I've had has always responded well to a lightened flywheel, not so much for the change in engine/power characteristics but more the difference it makes in how much easier the bike becomes to throw around.

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

Frame at paint shop and air box plug dropped off with carbon fibre guy.

Shits getting real.

Shits getting real.

- weeksy

- Site Admin

- Posts: 23416

- Joined: Sat Mar 14, 2020 12:08 pm

- Has thanked: 5450 times

- Been thanked: 13085 times

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

The frame is back from powder coat. The paint shop rang me this morning to let me know it was ready for collection but unfortunately I was already at Martin's for the penultimate - fingers crossed - tank fabrication session so I'll pick it up in the week.

The second hand 1098 flywheel courtesy of ebay arrived on Monday so I borrowed 20 minutes on a friend's lathe and turned it down and shed nearly half a kilo in weight in the process. Dropped that off with Nelly for him to throw in the engine and also got an update on engine progress, all good and should be finished this week.

Tank work this morning. Cut the tacks holding the top in place and removed it. Knocked all the dents and high spots out. Finished the pillion support frame and got the last remaining threaded bosses welded in....

Fully welded the top section, inside and out, so that can be fully linished so the welds disappear...

With that done the breather and drain pipes could be welded to the filler cap receptacle...

And that's it. Ready for final full assembly.

Next Saturday, we're working until it's finished.

The second hand 1098 flywheel courtesy of ebay arrived on Monday so I borrowed 20 minutes on a friend's lathe and turned it down and shed nearly half a kilo in weight in the process. Dropped that off with Nelly for him to throw in the engine and also got an update on engine progress, all good and should be finished this week.

Tank work this morning. Cut the tacks holding the top in place and removed it. Knocked all the dents and high spots out. Finished the pillion support frame and got the last remaining threaded bosses welded in....

Fully welded the top section, inside and out, so that can be fully linished so the welds disappear...

With that done the breather and drain pipes could be welded to the filler cap receptacle...

And that's it. Ready for final full assembly.

Next Saturday, we're working until it's finished.

- Skub

- Posts: 12167

- Joined: Mon Mar 16, 2020 5:32 pm

- Location: Norn Iron

- Has thanked: 9819 times

- Been thanked: 10144 times

Re: Ducati Multistretta 1098S

It's gonna be a keeper!

"Be kind to past versions of yourself that didn't know what you know now."

Walt Whitman

https://soundcloud.com/skub1955

Walt Whitman

https://soundcloud.com/skub1955

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: Ducati Multistretta 1098S

Just out of curiosity, who did you ask for the 3D printing? PM me if you can't say in public.

We use 3D printed parts in OEM applications (I'm a carbon fibre engineer in my day job) and there are some guys who can do pretty impressive stuff.

We use 3D printed parts in OEM applications (I'm a carbon fibre engineer in my day job) and there are some guys who can do pretty impressive stuff.

-

Supermofo

- Posts: 4999

- Joined: Mon Mar 16, 2020 3:39 pm

- Has thanked: 4359 times

- Been thanked: 2850 times

Re: Ducati Multistretta 1098S

I can't even imagine the violence that would be visited on anyone who ever damaged that tank!

Good work, looking forward to the finished bike. Should be entertaining to ride.

Good work, looking forward to the finished bike. Should be entertaining to ride.

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

https://www.central-scanning.co.ukMr. Dazzle wrote: ↑Sun Aug 02, 2020 8:28 pm Just out of curiosity, who did you ask for the 3D printing? PM me if you can't say in public.

We use 3D printed parts in OEM applications (I'm a carbon fibre engineer in my day job) and there are some guys who can do pretty impressive stuff.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: Ducati Multistretta 1098S

We use these guys for printing a lot. They have a new printing process from HP (I.e. the guys who made your ink jet printer circa 1997) that's good enough and cheap enough to make OEM supercar parts on the scale of 100 off. We buy bits from them which are visible to the final car customer (after being painted).

http://www.fdmdigitalsolutions.co.uk/

I'm curious about the airbox...since you are going to all this trouble with the tank, why haven't you integrated the tank and airbox like on Ducati superbikes? I.e. bottom of the tank is the top of the airbox? It probably won't make the tank any more complicated (as if that's possible!) and it'd save half an airbox. Does it not work with all the other cables etc?

http://www.fdmdigitalsolutions.co.uk/

I'm curious about the airbox...since you are going to all this trouble with the tank, why haven't you integrated the tank and airbox like on Ducati superbikes? I.e. bottom of the tank is the top of the airbox? It probably won't make the tank any more complicated (as if that's possible!) and it'd save half an airbox. Does it not work with all the other cables etc?

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

Re: Ducati Multistretta 1098S

I did consider it but packaging becomes an issue because the ECU sits on top of the airbox and the shape of the underside of the tank didn't lend itself well to sealing to an airbox bottom half.Mr. Dazzle wrote: ↑Mon Aug 03, 2020 9:28 am

I'm curious about the airbox...since you are going to all this trouble with the tank, why haven't you integrated the tank and airbox like on Ducati superbikes? I.e. bottom of the tank is the top of the airbox? It probably won't make the tank any more complicated (as if that's possible!) and it'd save half an airbox. Does it not work with all the other cables etc?

The big airbox as you are describing is a lot more work to do - I spoke to Felix at 2moto at length about the one he built for his 999/1098 hybrid - compared to what I've done and the gains it would potentially offer over a modified version of the OEM 1098 one and, given that I'd been aiming for 120bhp when I started the project, didn't IMO justify the extra effort.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: Ducati Multistretta 1098S

Fair enough.

The only Ducati I've done any spannering on is my old 996. I remember being quite impressed with just how frickin' big the airbox is compared to the outside size of the bike, plus the general clever packaging to get all that stuff in there. I suppose that also makes it a twat to modify

The only Ducati I've done any spannering on is my old 996. I remember being quite impressed with just how frickin' big the airbox is compared to the outside size of the bike, plus the general clever packaging to get all that stuff in there. I suppose that also makes it a twat to modify

-

millemille

- Posts: 850

- Joined: Wed Mar 18, 2020 11:40 am

- Has thanked: 304 times

- Been thanked: 1007 times

- weeksy

- Site Admin

- Posts: 23416

- Joined: Sat Mar 14, 2020 12:08 pm

- Has thanked: 5450 times

- Been thanked: 13085 times