How to stop exhaust slip joint from blowing

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

How to stop exhaust slip joint from blowing

I've recently fitted a pair of aftermarket exhaust cans and link pipes to my venerable old VFR and on one side there is a pronounced blow, so much so that it markedly leaned off the mixture when on the dyno. The joint has a spring closure, so it's not about to detach, but there is sufficient gap between header and link pipe that exhaust gases can escape.

I've tried exhaust cement and frankly it's shit. When it dries out, exhaust movement causes the dried paste to fracture and fall out. Is there any kind of thin film heat-resistant exhaust packing that anyone knows of? The gap it has to fill is probably only 1mm at maximum, but it's enough to cause a noticeable leak.

I've tried exhaust cement and frankly it's shit. When it dries out, exhaust movement causes the dried paste to fracture and fall out. Is there any kind of thin film heat-resistant exhaust packing that anyone knows of? The gap it has to fill is probably only 1mm at maximum, but it's enough to cause a noticeable leak.

There is no cloud, just somebody else's computer.

- Rockburner

- Posts: 4375

- Joined: Sun Mar 15, 2020 11:06 am

- Location: Hiding in your blind spot

- Has thanked: 7814 times

- Been thanked: 2527 times

Re: How to stop exhaust slip joint from blowing

I've always used silicon based flexi-sealant. As long as it's heat resistant and flexible it'll do the job.

The stuff that used to be the best was from "Dow Corning" if you can find it. It's not a "vehicle" specific stuff iirc.

The stuff that used to be the best was from "Dow Corning" if you can find it. It's not a "vehicle" specific stuff iirc.

non quod, sed quomodo

- Skub

- Posts: 12167

- Joined: Mon Mar 16, 2020 5:32 pm

- Location: Norn Iron

- Has thanked: 9819 times

- Been thanked: 10144 times

Re: How to stop exhaust slip joint from blowing

A thin copper strip annealed to fit?

"Be kind to past versions of yourself that didn't know what you know now."

Walt Whitman

https://soundcloud.com/skub1955

Walt Whitman

https://soundcloud.com/skub1955

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

Your comment jogged my memory - I've got some K2 High Temperature Silicone which is OK up to 325 deg C (allegedly) which should be way more than an exhaust system reaches, so that's an excellent shout. I was also thinking of getting some of this tape to pad out the gap and leave the silicone to do the final sealing:Rockburner wrote: ↑Thu Mar 28, 2024 3:50 pm I've always used silicon based flexi-sealant. As long as it's heat resistant and flexible it'll do the job.

The stuff that used to be the best was from "Dow Corning" if you can find it. It's not a "vehicle" specific stuff iirc.

It's safe up to 200 deg C for long term use, so should be OK. Does that sound like a Plan?

There is no cloud, just somebody else's computer.

- Rockburner

- Posts: 4375

- Joined: Sun Mar 15, 2020 11:06 am

- Location: Hiding in your blind spot

- Has thanked: 7814 times

- Been thanked: 2527 times

Re: How to stop exhaust slip joint from blowing

great wodge of sealant spread thickly should do the job. Just clean off any excess after assembly before it goes off.mangocrazy wrote: ↑Thu Mar 28, 2024 5:01 pmYour comment jogged my memory - I've got some K2 High Temperature Silicone which is OK up to 325 deg C (allegedly) which should be way more than an exhaust system reaches, so that's an excellent shout. I was also thinking of getting some of this tape to pad out the gap and leave the silicone to do the final sealing:Rockburner wrote: ↑Thu Mar 28, 2024 3:50 pm I've always used silicon based flexi-sealant. As long as it's heat resistant and flexible it'll do the job.

The stuff that used to be the best was from "Dow Corning" if you can find it. It's not a "vehicle" specific stuff iirc.

Kapton.JPG

It's safe up to 200 deg C for long term use, so should be OK. Does that sound like a Plan?

TBH - these days I just use any old silicon based bathroom sealant.... it still works.

non quod, sed quomodo

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

This stuff is black, but the exhaust joint is completely hidden by the belly pan, so I'm not too conerned about looks. But you're right - any old silicone will probably do the job fine.

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: How to stop exhaust slip joint from blowing

I had the chimney on my pizza oven sealed up with this stuff, way thicker than 1mm! I bet it's exactly the same stuff as high temp exhaust silicone.

https://shop.vitcas.com/heat-resistant- ... 310ml.html

https://shop.vitcas.com/heat-resistant- ... 310ml.html

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

That looks very similar to (if not the same as) this stuff I have (but had forgotten about):Mr. Dazzle wrote: ↑Thu Mar 28, 2024 7:01 pm I had the chimney on my pizza oven sealed up with this stuff, way thicker than 1mm! I bet it's exactly the same stuff as high temp exhaust silicone.

https://shop.vitcas.com/heat-resistant- ... 310ml.html

I'm pretty sure that I used the Vitcas product that you linked to when I was installing the woodburner flue in France.

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: How to stop exhaust slip joint from blowing

In the interest of fairness and a complete story, I should point out that said silicone failed  It went dry and crumbly and collapsed after about 2 summers of pizza oven use. But;

It went dry and crumbly and collapsed after about 2 summers of pizza oven use. But;

a) It was exposed to very hot gas. I'd guestimate it saw up to 750°C at times. I used it to seal between a stainless flue and a brick/cement oven. Right down at the businesss end it had flames licking it sometimes and the walls of the oven were hot enough that they (and the flue) were free of soot, which doesn't happen until you're well into the high hundreds on centigrade.

b) It lived outside in all weathers, and.

c) It's cheap enough to just re-apply after a couple of years if needed. When it does fail it just crumbles off leaving a clean surface again for the most part.

a) It was exposed to very hot gas. I'd guestimate it saw up to 750°C at times. I used it to seal between a stainless flue and a brick/cement oven. Right down at the businesss end it had flames licking it sometimes and the walls of the oven were hot enough that they (and the flue) were free of soot, which doesn't happen until you're well into the high hundreds on centigrade.

b) It lived outside in all weathers, and.

c) It's cheap enough to just re-apply after a couple of years if needed. When it does fail it just crumbles off leaving a clean surface again for the most part.

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

That's a pretty searching environment for any sealant to operate in. If you were to hazard a guess, what would exhaust gas temperature be roughly half way down a 4 cylinder bike exhaust system?Mr. Dazzle wrote: ↑Fri Mar 29, 2024 5:59 am In the interest of fairness and a complete story, I should point out that said silicone failedIt went dry and crumbly and collapsed after about 2 summers of pizza oven use. But;

a) It was exposed to very hot gas. I'd guestimate it saw up to 750°C at times. I used it to seal between a stainless flue and a brick/cement oven. Right down at the businesss end it had flames licking it sometimes and the walls of the oven were hot enough that they (and the flue) were free of soot, which doesn't happen until you're well into the high hundreds on centigrade.

b) It lived outside in all weathers, and.

c) It's cheap enough to just re-apply after a couple of years if needed. When it does fail it just crumbles off leaving a clean surface again for the most part.

There is no cloud, just somebody else's computer.

Re: How to stop exhaust slip joint from blowing

The temperature can definitely approach red-hot (460 degrees C) at full throttle and when you add in the vibration and shock nothing that isn't clamped stands much chance. I just put plenty of copper grease over the surfaces which forms a powder when the solvent parts burn off. Those spring loaded joints work much better if there is a seating ring, ideally conical, which mates the two parts at the end of the downpipe(s). A squarely mated edge joint held tightly with strong springs doesn't rely on a seal between the tubes which is never going to be achieved if some movement must be accommodated.

So my answer is dress the annular contact area at the end of the pipe and mount the system so that it stays square. Any air leak will make it impossible to accurately use a gas analyser sampling at the outlet, but leaks won't have much affect on actual power output.

So my answer is dress the annular contact area at the end of the pipe and mount the system so that it stays square. Any air leak will make it impossible to accurately use a gas analyser sampling at the outlet, but leaks won't have much affect on actual power output.

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

That's pretty much exactly what was observed on the dyno. Good point about concentrating on where the mating faces meet - I'll look closely at that.roadster wrote: ↑Fri Mar 29, 2024 9:25 am So my answer is dress the annular contact area at the end of the pipe and mount the system so that it stays square. Any air leak will make it impossible to accurately use a gas analyser sampling at the outlet, but leaks won't have much affect on actual power output.

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: How to stop exhaust slip joint from blowing

Exhaust gas itself easily reaches 800°C but your pipes wouldn't stand that for long  The valves have to put up with it though, so they're made of more exotic things. Some exhausts do get that hot, which is why F1 and the like uses Inconel for the exhausts.

The valves have to put up with it though, so they're made of more exotic things. Some exhausts do get that hot, which is why F1 and the like uses Inconel for the exhausts.

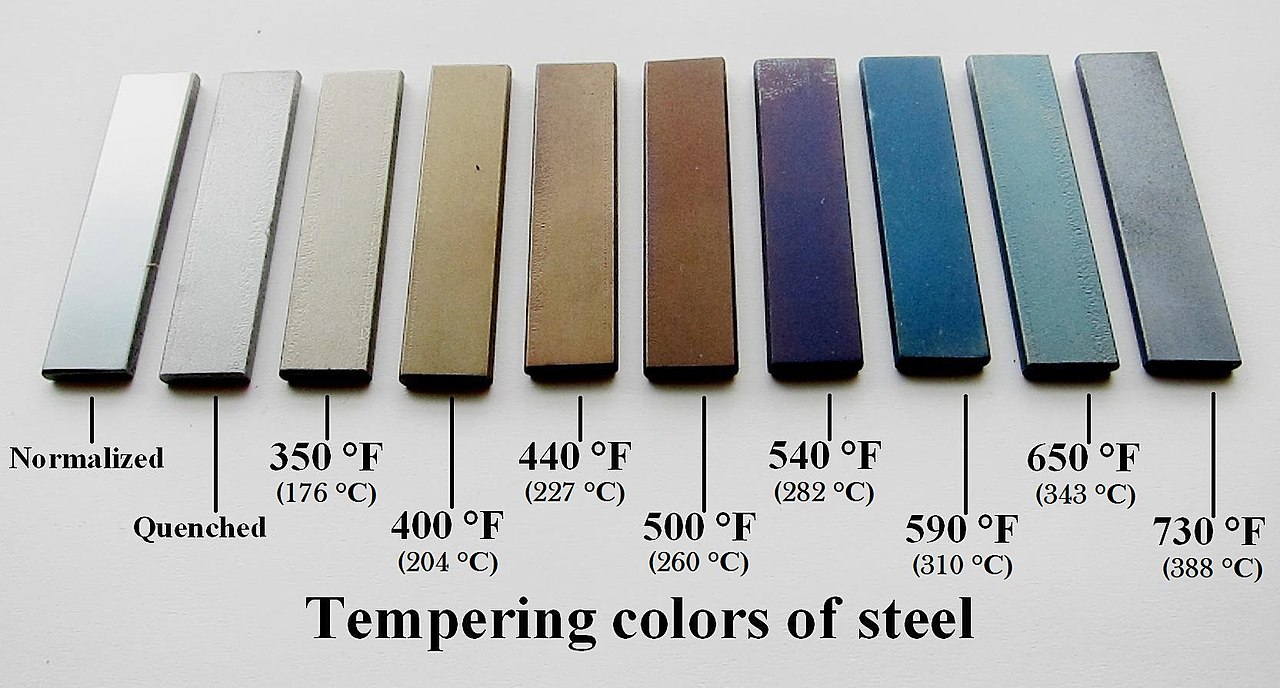

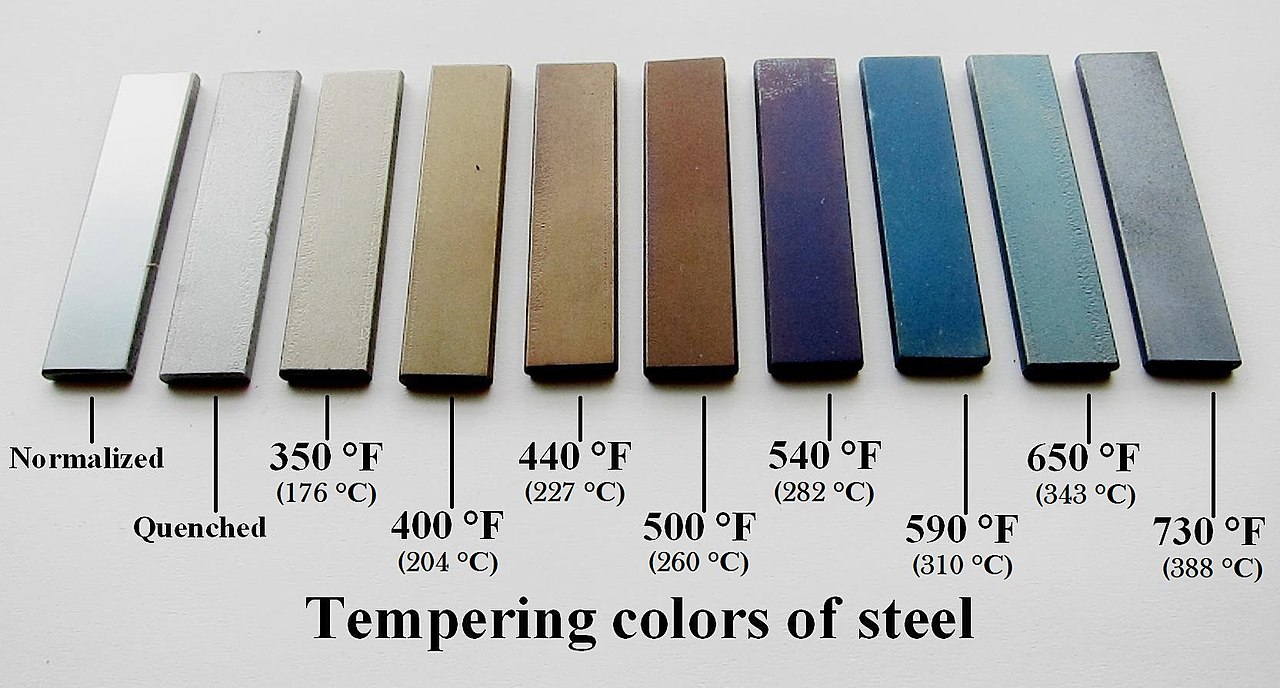

Down by the can on an old bike (which runs rich*) it's gonna be a couple of hundred at most I'd guess. If nothing else, the steel would be yellow/blue if it were much hotter.

*Fun fact..."running lean" typically isn't. Running lean generally actually means you're approaching being truly stoichiometric, which is the most efficient point to run at. 'cause it's the hottest. That's why modern engines are leaner burn. It's better. Until something melts.

Down by the can on an old bike (which runs rich*) it's gonna be a couple of hundred at most I'd guess. If nothing else, the steel would be yellow/blue if it were much hotter.

*Fun fact..."running lean" typically isn't. Running lean generally actually means you're approaching being truly stoichiometric, which is the most efficient point to run at. 'cause it's the hottest. That's why modern engines are leaner burn. It's better. Until something melts.

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

The stainless headers do have a warmish yellow hue (blueish at the exhaust ports), as do the link pipes, but I'd suggest age has had something to do with some of the discolouration.Mr. Dazzle wrote: ↑Fri Mar 29, 2024 10:11 am Exhaust gas itself easily reaches 800°C but your pipes wouldn't stand that for longThe valves have to put up with it though, so they're made of more exotic things. Some exhausts do get that hot, which is why F1 and the like uses Inconel for the exhausts.

Down by the can on an old bike (which runs rich*) it's gonna be a couple of hundred at most I'd guess. If nothing else, the steel would be yellow/blue if it were much hotter.

*Fun fact..."running lean" typically isn't. Running lean generally actually means you're approaching being truly stoichiometric, which is the most efficient point to run at. 'cause it's the hottest. That's why modern engines are leaner burn. It's better. Until something melts.

John (dyno man) talked a lot about A/F ratios (some of which went over my head), but I remember him saying that peak power is not made at true stoichimetric (14.7:1) but more likely at 12.5 - 13.5:1 . I just want it running 'nicely' with good throttle response, good power and good economy. You'll tell me now that those things are mutually exclusive...

There is no cloud, just somebody else's computer.

-

Mr. Dazzle

- Posts: 13937

- Joined: Mon Mar 16, 2020 7:57 pm

- Location: Milton Keynes

- Has thanked: 2550 times

- Been thanked: 6244 times

Re: How to stop exhaust slip joint from blowing

On me auld Bonnie the headers are a text book exercise in 'how hot did this steel get?'. The colours run the whole spectrum over about the first 100mm of pipe.

WRT AFR, it's mostly the fact that as you approach 14.7:1 it's harder and harder to make a practical engine. That AF ratio gives you the highest combustion temperature, and hence the most performance, if you ignore all the limitations of the whizzy metal bits. Kinda hard to ignore those in real life though!

Re: economy - not sure if it's still the case, but the most economical petrol piston engine in the world (outside a lab) used to be the Mercedes F1 lump. I'm talking in terms of BHP per unit of fuel consumed, not MPG. So yeah you can absolutely have power, economy and driveability. You just need F1 tech

But yeah...really we should say "rich" and "less rich" but that'd get confusing pretty quick.

WRT AFR, it's mostly the fact that as you approach 14.7:1 it's harder and harder to make a practical engine. That AF ratio gives you the highest combustion temperature, and hence the most performance, if you ignore all the limitations of the whizzy metal bits. Kinda hard to ignore those in real life though!

Re: economy - not sure if it's still the case, but the most economical petrol piston engine in the world (outside a lab) used to be the Mercedes F1 lump. I'm talking in terms of BHP per unit of fuel consumed, not MPG. So yeah you can absolutely have power, economy and driveability. You just need F1 tech

But yeah...really we should say "rich" and "less rich" but that'd get confusing pretty quick.

- mangocrazy

- Posts: 6892

- Joined: Tue Dec 22, 2020 9:58 pm

- Has thanked: 2402 times

- Been thanked: 3625 times

Re: How to stop exhaust slip joint from blowing

That's a nice practical demonstration. Most of the zorsts are between number 3 and 4 (176 - 204 deg C) with the bits adjacent to the exhaust ports looking like no. 7 (282 deg C). So my 315 deg C tolerant silicone should work just fine. I'm also hoping that with making the AFR 'less rich' that I'll get back some or all of the fuel economy I lost with my ill-advised jetting changes. The only part of the whole Sigma kit that had a positive effect was going up one size on the slow running jet. That definitely increased punch off the bottom end. The rest of the kit was a waste of space.

There is no cloud, just somebody else's computer.