https://www.bikeexif.com/hub-center-steering-motorcycle

Exhaustive build details and lots more pics here:

https://www.apriliaforum.com/forums/sho ... e-Hub-Bike

I've heard from more than one source that placing a radiator 'side on' to the airflow works at least as well as the 'head on' approach more universally favoured. Didn't the Britten have its radiator under the seat?

It depends on how the air is channeled through the rad.mangocrazy wrote: ↑Thu Feb 01, 2024 4:52 pmI've heard from more than one source that placing a radiator 'side on' to the airflow works at least as well as the 'head on' approach more universally favoured. Didn't the Britten have its radiator under the seat?

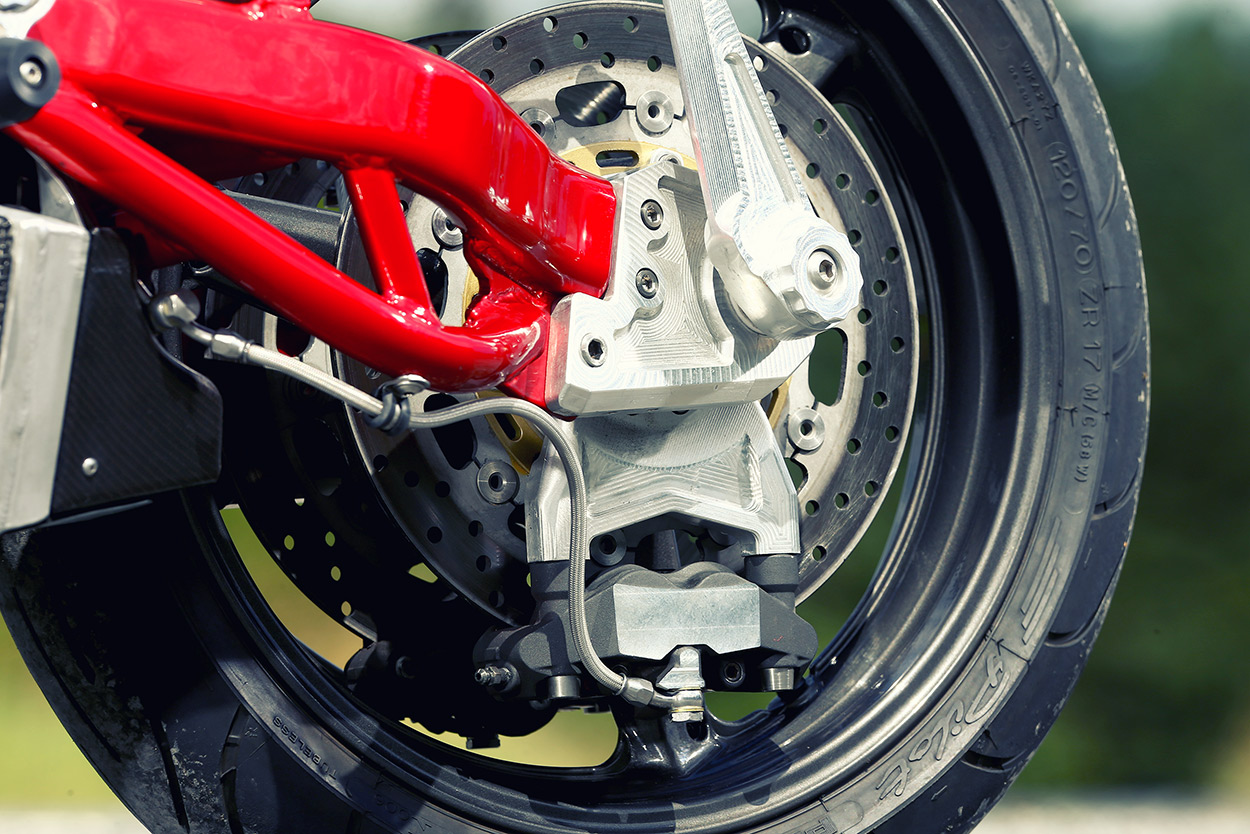

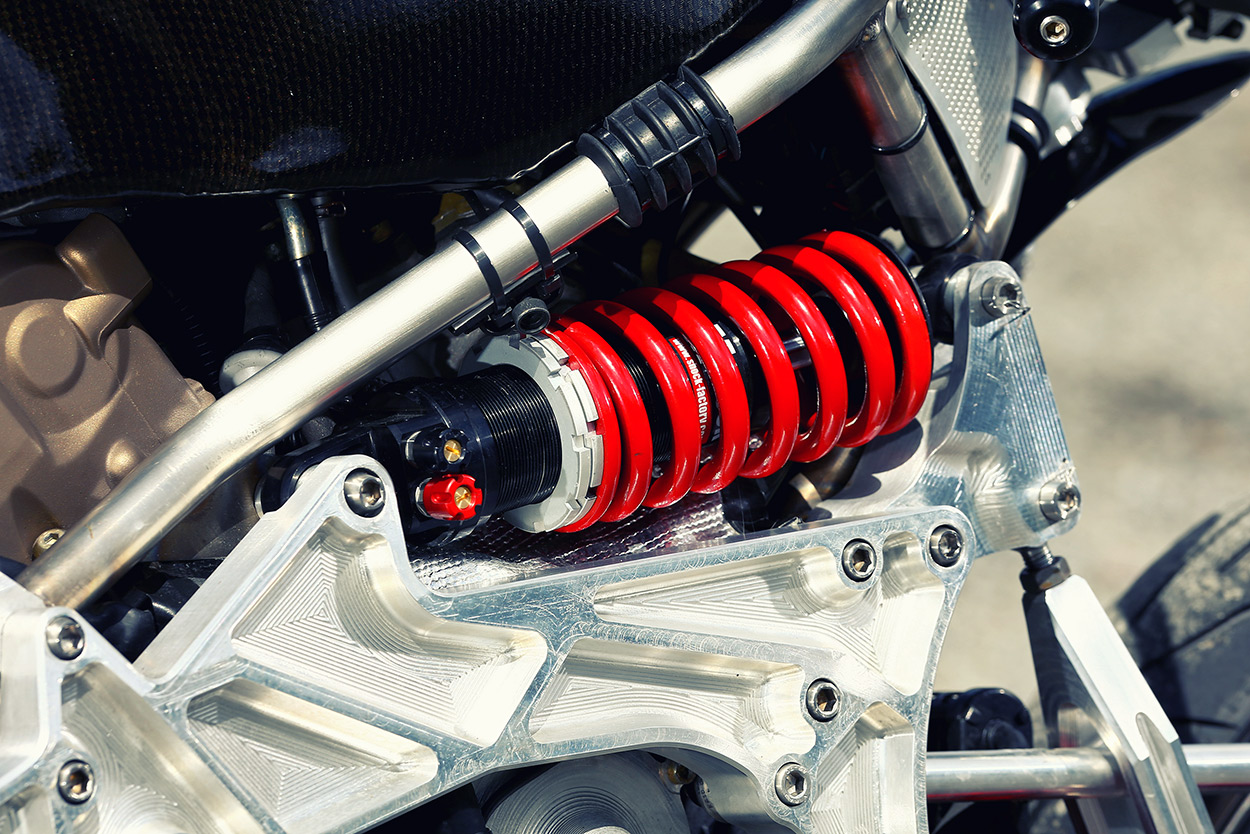

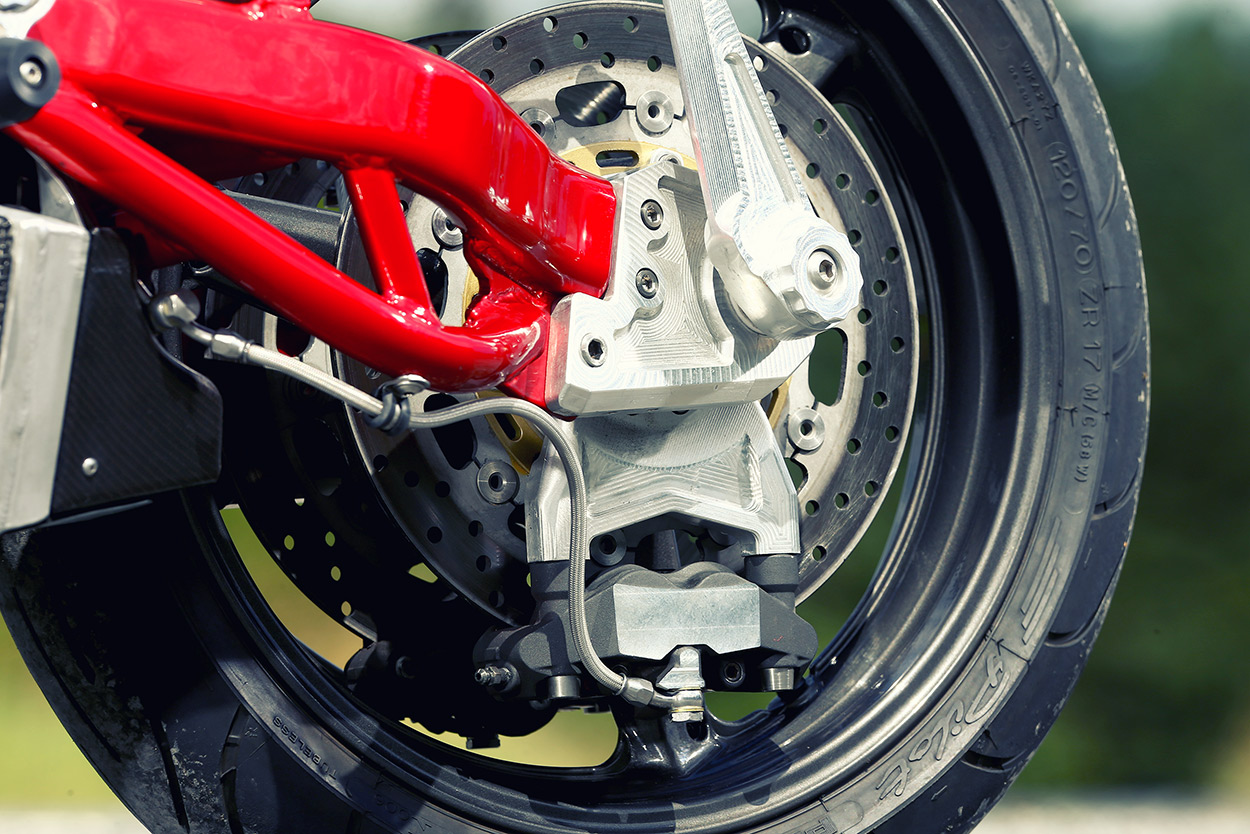

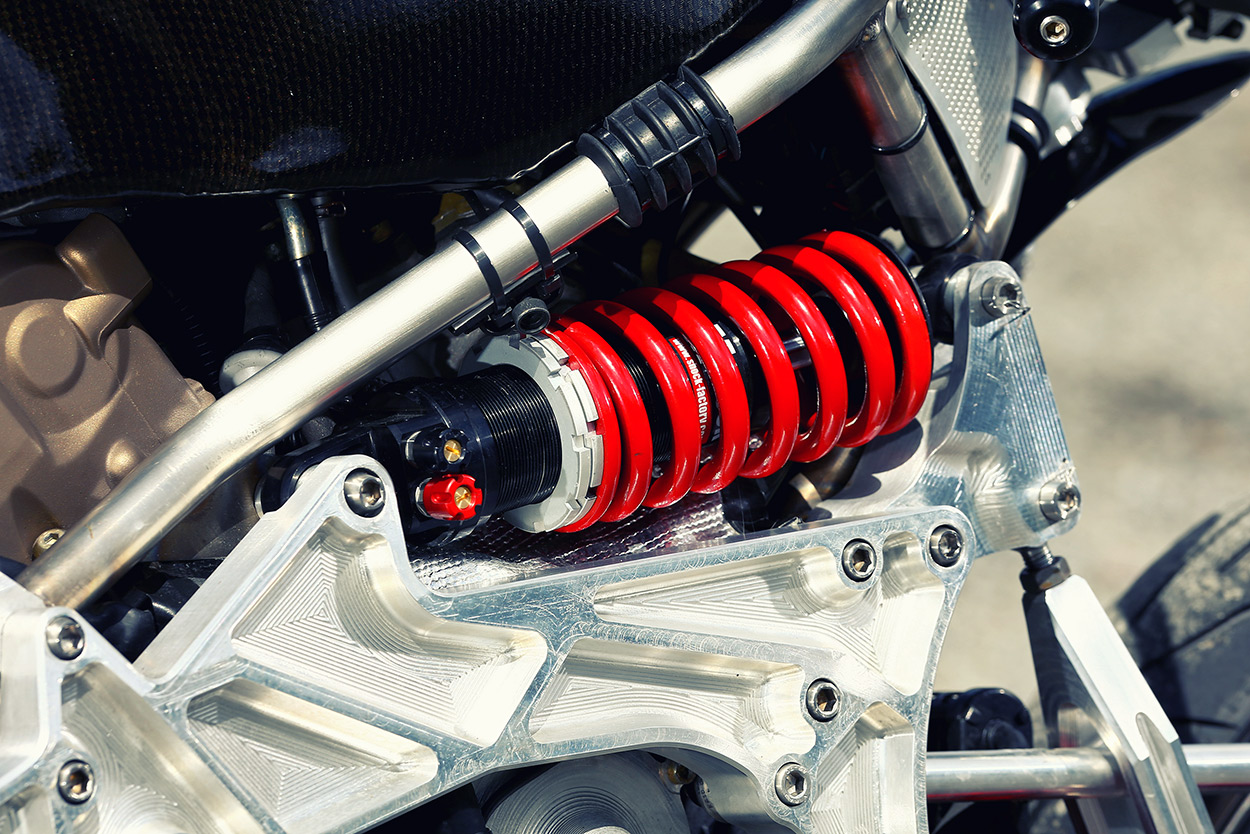

He didn't pay anyone for the original cuts either...he converted a manual mill to CNC in his shed/workshop 14 years ago. Kudos!Mr. Dazzle wrote: ↑Thu Feb 01, 2024 7:11 pm I wouldn't pay someone to spend ages doing final fine cuts if it was a shed project either.

I mean...well, I would, but only because those sharp step overs make loads of potential crack initiators.

I wouldn't do it for aesthetic reasons!

Yeah I saw that. It's even more impressive when you consider that's probably Windows Vista eraCount Steer wrote: ↑Thu Feb 01, 2024 7:31 pmHe didn't pay anyone for the original cuts either...he converted a manual mill to CNC in his shed/workshop 14 years ago. Kudos!Mr. Dazzle wrote: ↑Thu Feb 01, 2024 7:11 pm I wouldn't pay someone to spend ages doing final fine cuts if it was a shed project either.

I mean...well, I would, but only because those sharp step overs make loads of potential crack initiators.

I wouldn't do it for aesthetic reasons!

Hold my beer...Mr. Dazzle wrote: ↑Thu Feb 01, 2024 7:39 pmYeah I saw that. It's even more impressive when you consider that's probably Windows Vista eraCount Steer wrote: ↑Thu Feb 01, 2024 7:31 pmHe didn't pay anyone for the original cuts either...he converted a manual mill to CNC in his shed/workshop 14 years ago. Kudos!Mr. Dazzle wrote: ↑Thu Feb 01, 2024 7:11 pm I wouldn't pay someone to spend ages doing final fine cuts if it was a shed project either.

I mean...well, I would, but only because those sharp step overs make loads of potential crack initiators.

I wouldn't do it for aesthetic reasons!