Been making a 2200 centigrade furnace in my shed

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Been making a 2200 centigrade furnace in my shed

This is the six one I've made, they run at 2200c in argon gas or 2000c with vacuum. It's not finished yet, it will have a linear drive to open the lid. Designed and manufactured out of my garage/shed.

They've all gone to Japan, mainly Universities, they do like making things hot over there!

They've all gone to Japan, mainly Universities, they do like making things hot over there!

- Attachments

-

- 2inch Furnace.jpg (268.5 KiB) Viewed 1392 times

-

- IMG_6485.JPG (461.48 KiB) Viewed 1392 times

- Yorick

- Posts: 16736

- Joined: Sat Mar 14, 2020 8:20 pm

- Location: Paradise

- Has thanked: 10263 times

- Been thanked: 6886 times

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

I can't afford the time (money) to make one for myself, it would be nice to play around melting titanium or platinum into graphite moulds.

The Japanese use them for annealing 2" silicon carbide wafers amongst other things.

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

Thanks, they are expensive at £7250 but a lot of time and parts go into making one, my Japanese agent sells them for twice that, it's hard sell in Japan without an agent. If I could get my website working for me, perhaps I could sell more direct to customers and actually make a living wage!

-

demographic

- Posts: 3028

- Joined: Mon Mar 16, 2020 9:30 pm

- Location: Less that 50 miles away from Moscow, but which one?

- Has thanked: 1346 times

- Been thanked: 1722 times

Re: Been making a 2200 centigrade furnace in my shed

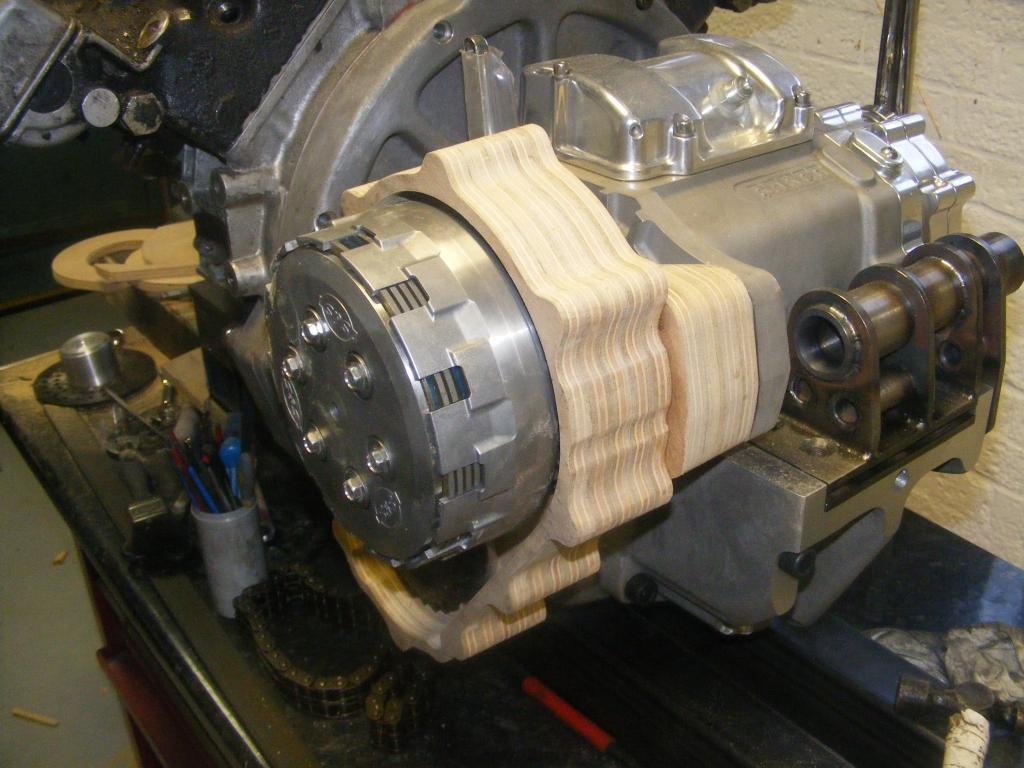

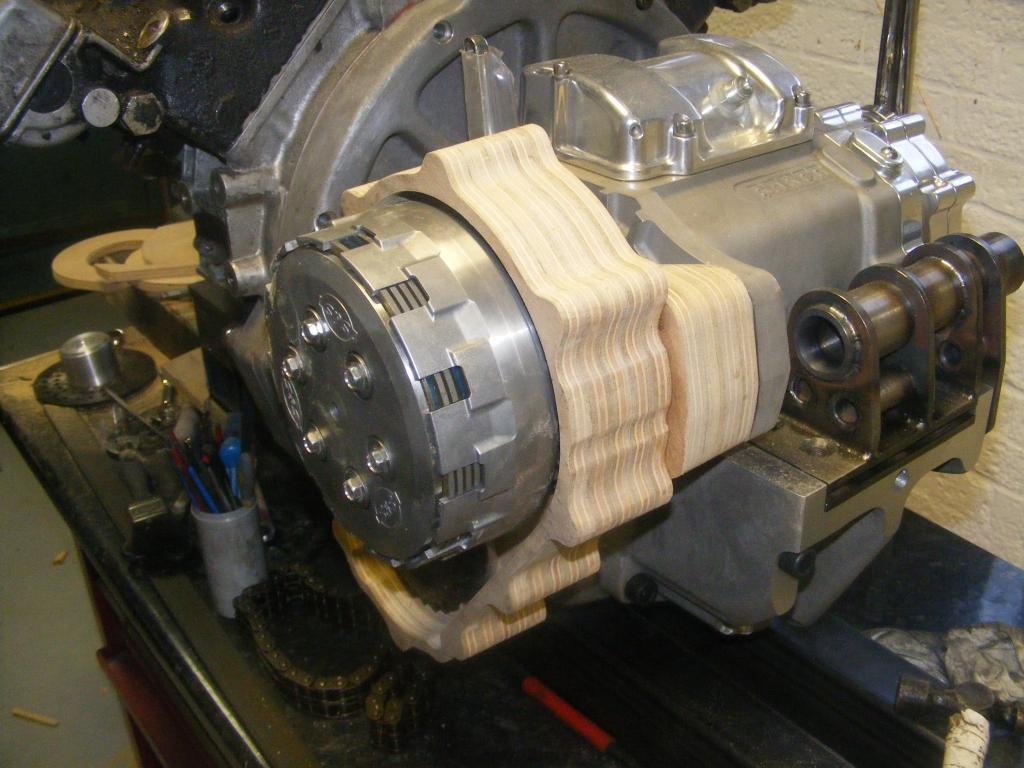

Is it you making the Maserati Barber engined bike as well?

Thats a bit posh.

Tell us more, I assume this is a mockup for getting casings cast and general testing if it'll fit?

Thats a bit posh.

Tell us more, I assume this is a mockup for getting casings cast and general testing if it'll fit?

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

That's one I've been working on for years. I started a business making furnaces and heaters about 3 years ago and it's got in the way of my bike building.

- Attachments

-

- 942948587_orig.jpg (272.69 KiB) Viewed 1342 times

-

- maseratiV6.jpg (273.26 KiB) Viewed 1342 times

-

- castings-model.jpg (281 KiB) Viewed 1342 times

-

demographic

- Posts: 3028

- Joined: Mon Mar 16, 2020 9:30 pm

- Location: Less that 50 miles away from Moscow, but which one?

- Has thanked: 1346 times

- Been thanked: 1722 times

Re: Been making a 2200 centigrade furnace in my shed

So with that clutch cover, is it a plug/pattern for sand casting?

What allowance do you have to give for shrinkage or can the cast part it be machined to final dimension afterwards? I read up a bit on this years ago in the product tech section of an industrial radiography course but other than some of my exam test pieces being castings I only worked on weldments after my tests then Ive been out of that game for about 20 odd years so my terminology might be a good bit wide of the mark/just plain wrong.

Also, I'm guessing you routed the layers with a bearing guided cutter so they will all be as near as dammit the same size so the final part will have to be sandcast (which is pretty much the way most low volume casting is done anyway IIRC) as it wont have draft angles for mold release.

It's a long time since I looked at any of this so please excuse and correct any of that thats just bollocks. I'm not (too) embarrassed to be proven wrong if it means I learn something in the process.

What allowance do you have to give for shrinkage or can the cast part it be machined to final dimension afterwards? I read up a bit on this years ago in the product tech section of an industrial radiography course but other than some of my exam test pieces being castings I only worked on weldments after my tests then Ive been out of that game for about 20 odd years so my terminology might be a good bit wide of the mark/just plain wrong.

Also, I'm guessing you routed the layers with a bearing guided cutter so they will all be as near as dammit the same size so the final part will have to be sandcast (which is pretty much the way most low volume casting is done anyway IIRC) as it wont have draft angles for mold release.

It's a long time since I looked at any of this so please excuse and correct any of that thats just bollocks. I'm not (too) embarrassed to be proven wrong if it means I learn something in the process.

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

I made the patterns by slicing my 3D model in to 12mm slivers, these were stuck to ply, which I cut out with a jigsaw, I glued all the layers together and then used a boobin sander with 3 degree angled table to sand the ply model with a draft angle. Next time I'll 3D print the pattern for sand casting or perhaps lost wax/PLA , I think the latter is the way to go.demographic wrote: ↑Sat Sep 05, 2020 2:52 pm So with that clutch cover, is it a plug/pattern for sand casting?

What allowance do you have to give for shrinkage or can the cast part it be machined to final dimension afterwards? I read up a bit on this years ago in the product tech section of an industrial radiography course but other than some of my exam test pieces being castings I only worked on weldments after my tests then Ive been out of that game for about 20 odd years so my terminology might be a good bit wide of the mark/just plain wrong.

Also, I'm guessing you routed the layers with a bearing guided cutter so they will all be as near as dammit the same size so the final part will have to be sandcast (which is pretty much the way most low volume casting is done anyway IIRC) as it wont have draft angles for mold release.

It's a long time since I looked at any of this so please excuse and correct any of that thats just bollocks. I'm not (too) embarrassed to be proven wrong if it means I learn something in the process.

I have a superb local foundry, who cast all kinds of awesome things like vincent heads, V16 Auto Union engine blocks, alloy blocks for racing jags, maserati birdcage cylinder heads, they were so helpful and encouraging and did all the casting for £300 cash. I can't remember exactly what the shrinkage was, I think it was about 1.5% linear shrinkage, the foundry at the time looked at my drawings and estimated the shrinkage for me and I enlarged the pattern by that amount.

-

demographic

- Posts: 3028

- Joined: Mon Mar 16, 2020 9:30 pm

- Location: Less that 50 miles away from Moscow, but which one?

- Has thanked: 1346 times

- Been thanked: 1722 times

Re: Been making a 2200 centigrade furnace in my shed

Ahh, nice one.

I saw your furnace then your username and figured there had to be more to it.

Hit Google with your username and as expected there was other interesting stuff to see.

I'd not got so far stalking your projects as to find out you'd actually got the casings made up and just assumed you'd painted your pattern.

There is a type of bearing guided router cutter that might have done those after the first one was made as a pattern.

Its used to put a leading edge onto a door and has a very slight undercut angle of 3 degrees which might do the same job as the sander? Max depth of cut is 50mm so mebbeel not good enough.

Depends on what tools you have avalible and its not an issue now but just in case you need to do one in the future?

https://www.mtmc.co.uk/Trend-TR39-Beari ... 34930.aspx

I saw your furnace then your username and figured there had to be more to it.

Hit Google with your username and as expected there was other interesting stuff to see.

I'd not got so far stalking your projects as to find out you'd actually got the casings made up and just assumed you'd painted your pattern.

There is a type of bearing guided router cutter that might have done those after the first one was made as a pattern.

Its used to put a leading edge onto a door and has a very slight undercut angle of 3 degrees which might do the same job as the sander? Max depth of cut is 50mm so mebbeel not good enough.

Depends on what tools you have avalible and its not an issue now but just in case you need to do one in the future?

https://www.mtmc.co.uk/Trend-TR39-Beari ... 34930.aspx

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

That tool would work, I did struggle making the patterns. I now have a CNC router so I could finish cut each layer and glue together I've been playing with 3D printers, it's possible to print in low melting point plastic and use the lost wax method, no need for multi piece patterns and plugs, simply print the most intricate patterns you want and cast. I'd like ( if I live long enough!) to cast some cases for a 1000cc single cylinder bike engine with a balance rod like the supermono Ducati but with vertical cylinder and balance rod out the front, I have the crankshafts but not the timedemographic wrote: ↑Sat Sep 05, 2020 5:17 pm Ahh, nice one.

I saw your furnace then your username and figured there had to be more to it.

Hit Google with your username and as expected there was other interesting stuff to see.

I'd not got so far stalking your projects as to find out you'd actually got the casings made up and just assumed you'd painted your pattern.

There is a type of bearing guided router cutter that might have done those after the first one was made as a pattern.

Its used to put a leading edge onto a door and has a very slight undercut angle of 3 degrees which might do the same job as the sander? Max depth of cut is 50mm so mebbeel not good enough.

Depends on what tools you have avalible and its not an issue now but just in case you need to do one in the future?

https://www.mtmc.co.uk/Trend-TR39-Beari ... 34930.aspx

- KungFooBob

- Posts: 14201

- Joined: Sat Mar 14, 2020 1:04 pm

- Location: The content of this post is not AI generated.

- Has thanked: 539 times

- Been thanked: 7528 times

Re: Been making a 2200 centigrade furnace in my shed

I'm an idiot, bear this in mind when you answer my stupid question.

If 2200 is hot enough to melt titanium, what is the main body made out of so it doesn't melt?

If 2200 is hot enough to melt titanium, what is the main body made out of so it doesn't melt?

-

David

- Posts: 2134

- Joined: Tue Mar 17, 2020 8:50 am

- Location: Top 'o the Worle

- Has thanked: 218 times

- Been thanked: 689 times

Re: Been making a 2200 centigrade furnace in my shed

Something with a higher melting point?KungFooBob wrote: ↑Sat Sep 05, 2020 7:11 pm I'm an idiot, bear this in mind when you answer my stupid question.

If 2200 is hot enough to melt titanium, what is the main body made out of so it doesn't melt?

-

demographic

- Posts: 3028

- Joined: Mon Mar 16, 2020 9:30 pm

- Location: Less that 50 miles away from Moscow, but which one?

- Has thanked: 1346 times

- Been thanked: 1722 times

Re: Been making a 2200 centigrade furnace in my shed

Think its usually a refractory material with cement, sand and err... something else I can't remember. Vermiculite?

But 2200 degrees C is fairly going some and I'm guessing its above most backyard furnaces.

But 2200 degrees C is fairly going some and I'm guessing its above most backyard furnaces.

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

The hot-zone is a 55mm diameter flat graphite element suspended in a tungsten housing, this acts as a reflector, this is in the middle of a 150mm diameter water cooled chamber, packed with graphite felt insulation.KungFooBob wrote: ↑Sat Sep 05, 2020 7:11 pm I'm an idiot, bear this in mind when you answer my stupid question.

If 2200 is hot enough to melt titanium, what is the main body made out of so it doesn't melt?

The power required to get to 2000c is about 1.6Kw, which is almost half the power of a kettle

- Attachments

-

- INSULATION.jpg (197.39 KiB) Viewed 1288 times

-

CrossbreedCycles

- Posts: 10

- Joined: Thu Sep 03, 2020 10:20 am

- Has thanked: 10 times

- Been thanked: 8 times

Re: Been making a 2200 centigrade furnace in my shed

This was the first one I built, the chamber is a bit smaller and the hot-zone only 30mm diameter, here it is running at 2000c

- Attachments

-

- Running-2000C.jpg (307.88 KiB) Viewed 1285 times